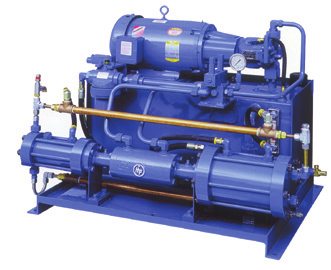

Inert gas foaming typically uses compressed carbon dioxide (CO2) or nitrogen (N2) at pressures of 10,000 psig (69 MPa) or less. These gases are used as physical blowing agents in the production of foamed plastics for various manufactured products. Our LX-SERIES gas compressors and systems are the standard machine used for boosting the pressure with these gases.

INERT GAS FOAMING

FEATURES

- Oil-free non-lubricated gas pistons and protect against oil contamination of the process gas.

- Full stroke-length distance pieces isolate the hydraulic drive from the gas cylinders. This prevents contamination of the gas by the hydraulic drive oil.

- Hydro-Pac gas compressors work over a wide range of inlet pressures. In many cases inlet pressure regulators are not required.

- Intensifiers are ideally suited for high pressures due to the simple geometry, slow operating speeds and in-line loads.

- Oil-free non-lubricated gas pistons and protect against oil contamination of the process gas.

- Full stroke-length distance pieces isolate the hydraulic drive from the gas cylinders. This prevents contamination of the gas by the hydraulic drive oil.

- Hydro-Pac gas compressors work over a wide range of inlet pressures. In many cases inlet pressure regulators are not required.

- Intensifiers are ideally suited for high pressures due to the simple geometry, slow operating speeds and in-line loads.

- Standard operating ranges for this line are:

- Discharge pressures: 1,000 to 12,000 psig

- Inlet pressure range: 70 to 6,000 psig

- Capacity ranges: <1 scfm to >300 scfm

- The LX-SERIES compressor can be used for heavy duty low-pressure applications or gas scavenging (reclaim) application to use all of the available gas in the cylinders.