Hot isostatic pressing (H.I.P.) is a high-temperature, high-pressure manufacturing process used to eliminate impurities in metal castings and other materials.

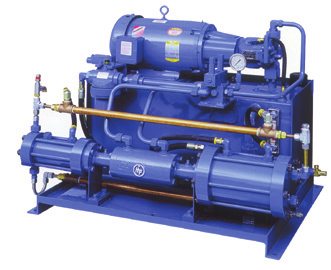

Our experience includes manufacturing compressors, valve racks and high-pressure vessels for hot isostatic pressing applications at pressure ranges from 10,000 to 60,000 psig (69 to 414 MPa). The process gas is typically argon but some H.I.P. applications have used nitrogen and helium gases

HOT ISOSTATIC PRESSING H.I.P.

FEATURES

- Robust, reliable, low-maintenance design.

- Oil-free non-lubricated gas pistons and protect against oil contamination of the process gas.

- Patented free piston design allows quick change •of high-pressure seals without untorquing the intensifier.

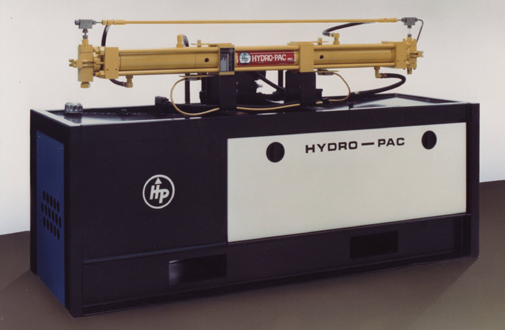

- Compressors feature an intensifier with electro-•hydraulic power units. This eliminates the need for drive air.

- Patented free piston design allows for •maintenance on the high-pressure seals without removing the hydraulic section.

- Water-cooled intensifier allows higher compression ratios which reduces the number of stages.

- Hydro-Pac gas compressors work over a wide range of inlet pressures. In many cases inlet pressure regulators are not required.

- Compressors available in two-stage, single stage and with rapid cool valving. Each configuration allows various inlet conditions.

- Custom valve racks can be quoted with any machine

- Standard operating ranges for this line are:

- Discharge pressures: 1,000 to 12,000 psig

- Inlet pressure range: 70 to 6,000 psig

- Capacity ranges: <1 scfm to >300 scfm

- The LX-SERIES compressor can be used for heavy duty low-pressure applications or gas scavenging (reclaim) application to use all of the available gas in the cylinders.

- Standard discharge pressures: 10,000 to 30,000 psig

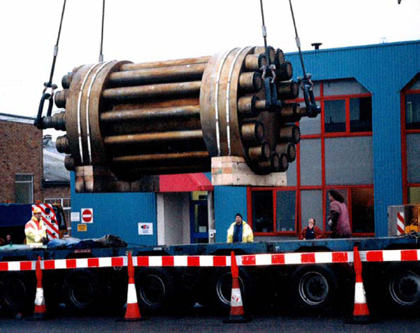

- Standard ID: 6 to 52 inches (152 to 1321 mm)

- Closure types: Full thread, breach thread (quarter turn) and pin.

- Designs: Monobloc, Tie-rod, Multi-Wall and other special designs.

- Codes: ASME Section VIII, Division 1, 2, or 3; PED (Europe); KHK (Japan); or non-code designs.

- Machined from forgings or bar stock.

- Speciality vessel designs.